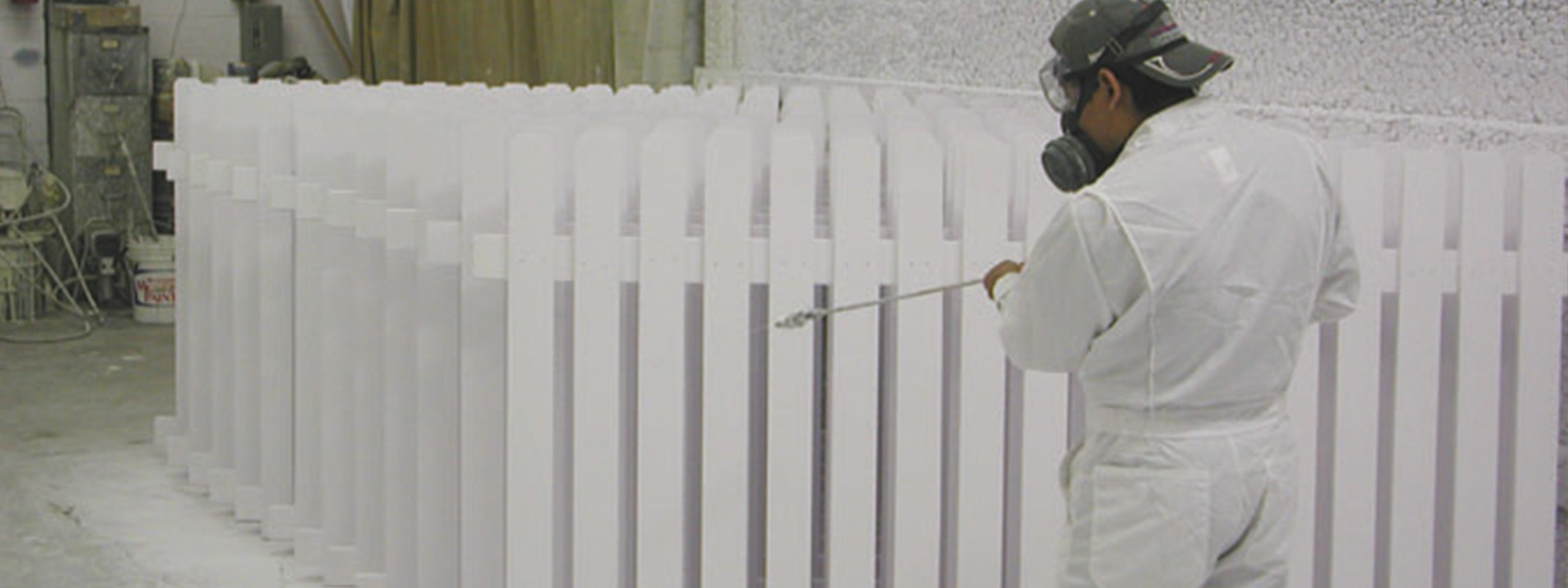

Stain Shop – Fence Factory Inc.

Once your fence is built we offer the additional service of staining. Our indoor stain facility provides a clean, dry, climate controlled environment to ensure the best possible finish.

In order to achieve a superior finish, Fence Factory follows these 6 steps:

- Properly drying the wood. The wood is stacked in a way to allow maximum air flow which removes moisture from the wood.

- Sanding and filling. Our craftsmen use a high performance air filler to fill nail holes and slight imperfections in the cedar. Then all material is sanded and prepared for staining. This step is essential to achieve a smooth surface.

- Prime the wood. Cedar, like most woods contains a small amount of tanin. The primer coat seals the wood to maximize the cedars natural tanin bleeding.

- Application of the top coat. Two applications of a solid stain are performed with drying time between.

- Stacking and delivering. Althrough at first glance it may seem insignificant, this step insures the fence arrives in proper condition. The fence sections are stacaked with layers of wax paper in between. Once they are delivered to the installation site they are unloaded and again staacked with wax paper between the sections.

- Installation and touch-up work. Once the installers have completed the installation of your custom built and stained fence, our team of painters arrive to fill any screw holes that resulted from the installation and perform any necessary touch-up painting.

This extensive process is necessary to provide you with the finest stained product.